Product Description

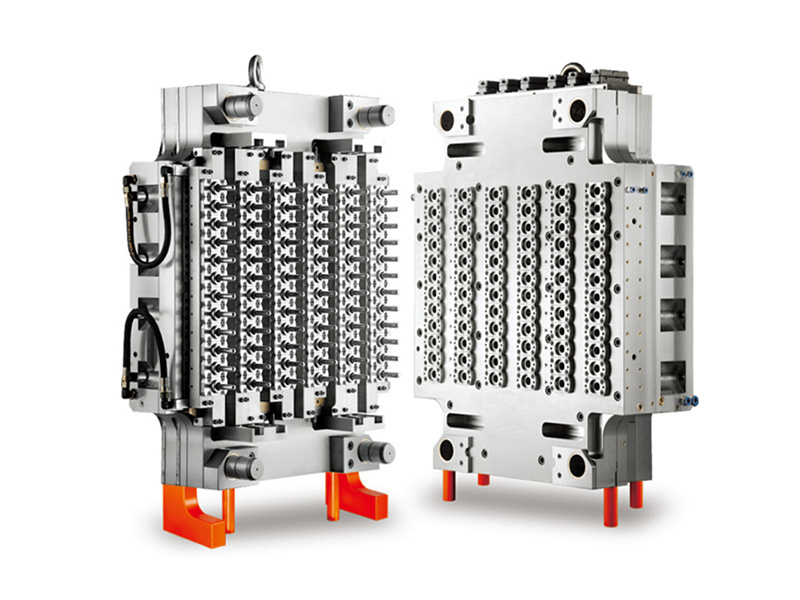

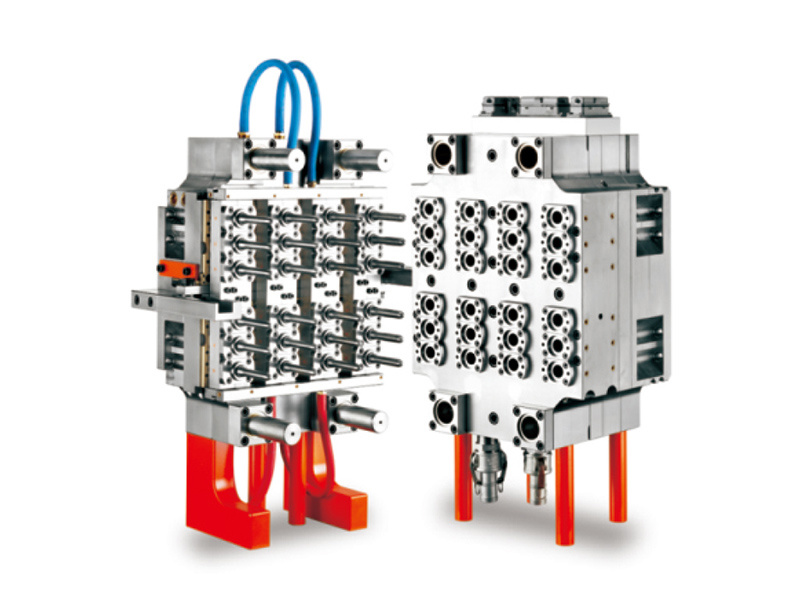

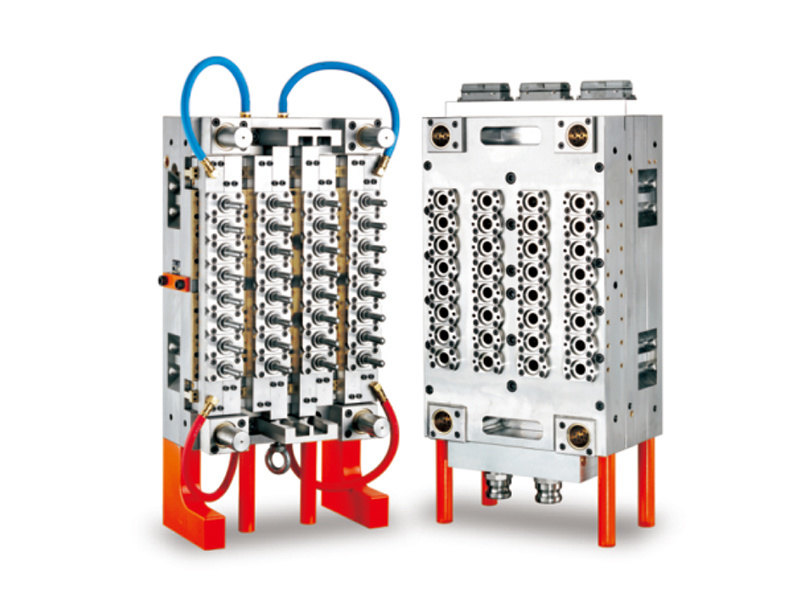

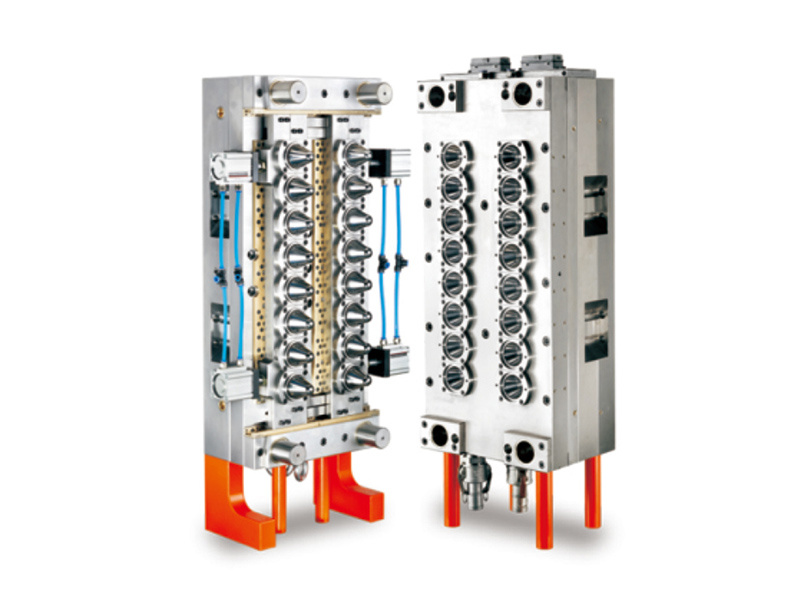

Preform lnjection Mould from 1 cavity wide mouth jar and gallon bottle preform up to 96 cavities narrow neck

preform mould;

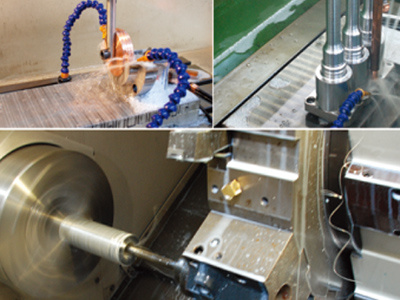

Tube blank is desianed with the help of computer, which surely contributes to the increasing of Bottle yeild; Employed internationally advanced two-step dual taper locating technology. Each cavity self-locks independentlyto ensurelow rate of decentration;

Core and cavity are made of special mould steel after preheating treatmentin the original factory in Sweden.individual temperature control of all cavity;

Lip cavity is made ofimported nitrated steel, which is of high hardness and longservice life,in accordance withinternational standard;

The excellent hot runner design assures uniform heating and greatly improves thequality of plastic product;

No cuting of gate is employed to reduce the labor intensity; Standard inter-changeable mould components;

The life of mould is more than 2 million times.

MOULD DATA

| NO,OF CAVITY | 24-Cavity | 32-Cavity | 48-Cavity | 72-Cavity | 96-Cavity |

| Dimension of 18g preform(HxLxW) | 785x500x520 | 860x600x530 | 1120x635x580 | 1090x780x580 | 1380x850x600 |

| Weight(kg) | 1700 | 2100 | 2600 | 3200 | 4500 |

All specifications and designs are subject to change without notice.

Key words:

Mould

Related Products

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.