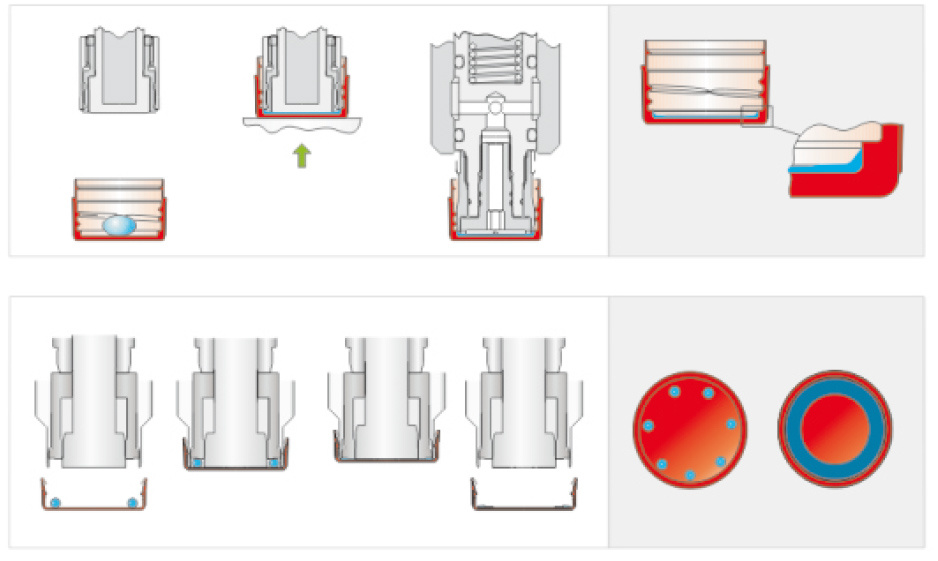

This machine is mainly used for making inner liner for anti-theftaluminium caps and plastic caps.lt takes the dried domesticand imported EVA plastic grains as raw materials. After beingplasticised, moulded and pressed into lids by high temperature.the inner liner is conglutinated with bottle cap.The machine solves the previous problems of water and gasleakage without liner. Take manual liner putting as an example,it is unhygienic, probably put two pieces together or forget toput, and low work efficiency.The machine has small size, high efficiency, easy operation,smooth and beautiful inner liner, which makes cap easy to openwith good sealing.In line with the national food hygienestandards, Our products have same characteristics comparedwith imported bottle caps and molding machines. Our companyalso provides special lining machine, lining formula, productiontechniques, lining caps moulds, cap slitting machines and all setof services.

Product Description

MAIN TECHNICALFEATURES

| ITEMS | DR-280A |

| Arrangement of lids feeding | automatic lids feeding |

| Output/hour | 10000-12000(pieces/hour) |

| Heat energy controls | temperature controls automatically |

| Weight of the liner | 0.35-0.40(g/piece) |

| Eletricity consumption of the machine | 11KW |

| Power of the host machine | 3KW |

| Electrical source | ≈380W 50HZ |

| Power of the assistant machine | 3KW |

| Weight | 1.6T |

| Controlled method | electric machine and linkage controls |

| Dimension | 3150×1100×1550 |

| Timing mode | electric machine frequency conversion timing |

All specifications and designs are subject to change without notice.

Key words:

Cap Lining Machine

Related Products

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.